AEROSPACE

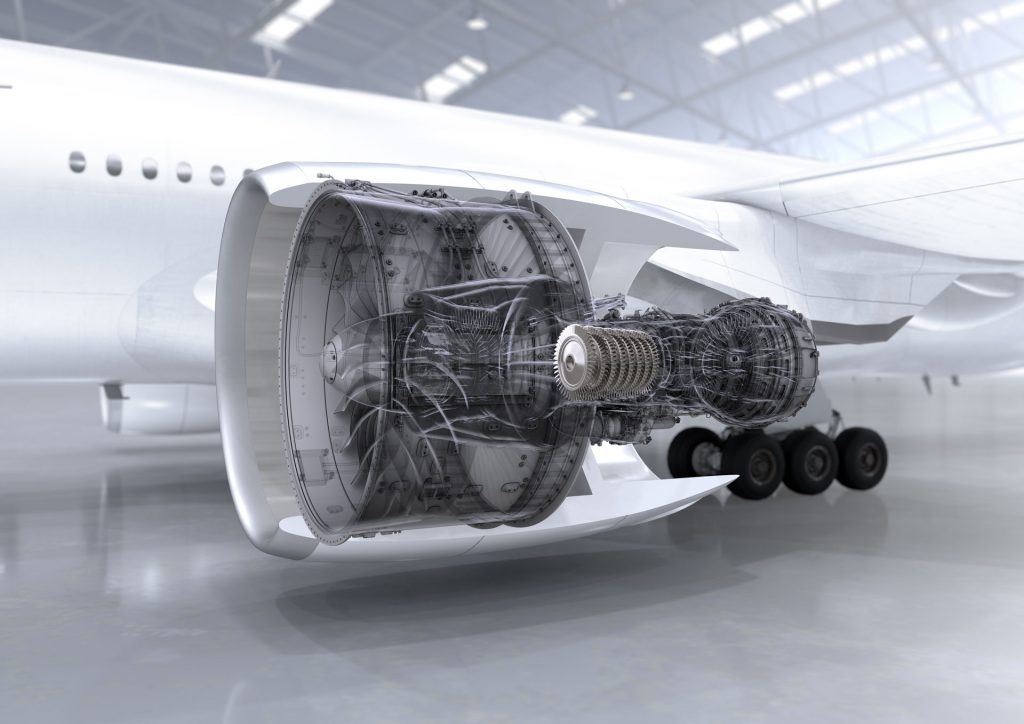

In the aerospace industry, titanium capillaries are primarily used for fluid and gas systems, including fuel, lubrication, and cooling systems.

For example, in aircraft fuel systems, titanium capillaries are used to transport fuel from the main tank to the engine. The small diameter of the capillaries allows for a high-pressure fuel system that is lightweight and efficient, and the corrosion-resistant properties of titanium make it well suited for use in this application, where the capillaries are exposed to the fuel and other corrosive fluids.

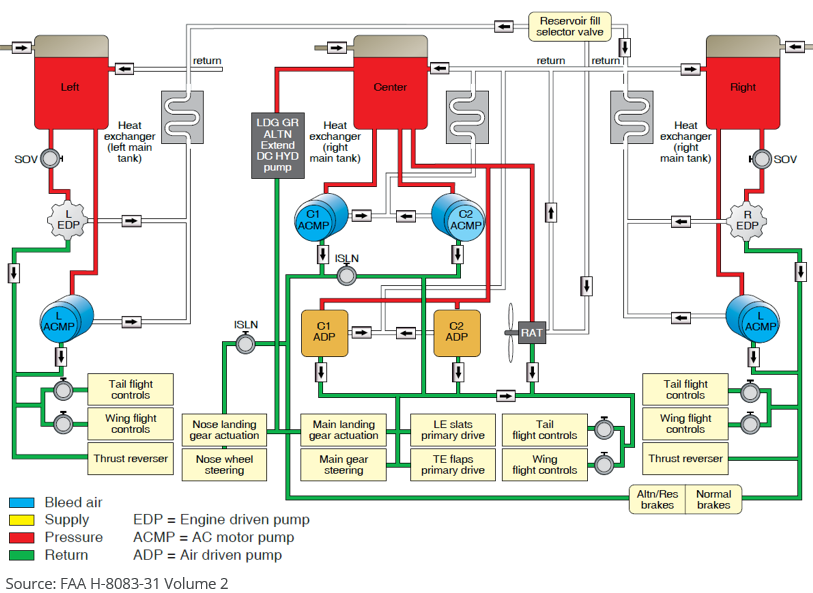

Another application for titanium capillaries in aerospace industry is in Hydraulic systems. The capillaries are used to transport the hydraulic fluid under high pressure, the corrosion resistance and high strength properties of titanium make it suitable for these system where high reliability is needed.

Titanium capillaries are also used in cooling systems for aircraft engines, where they are used to transport coolant to the engine to keep it from overheating. The small diameter of the capillaries allows for a lightweight and efficient system, while the high resistance to heat makes titanium well suited for use in this application.

In summary, the use of titanium capillaries in aerospace industry mainly stems from the need for high corrosion resistance, high strength, and high reliability in the systems where they are used, as well as the overall weight reduction to improve aircraft performance.

At Stahlmann, we manufacture pure titanium Gr.1 and Gr.2 capillary tubes as well as Gr.9 alloy capillary tubes for Aerospace industry application, due to its super light, high strength, and high corrosion resistance attributes. These materials are found in applications such as heat exchanger, instrumentation, and pressure tubing.